Table of Contents

What is Skin Effect in Transmission Lines?

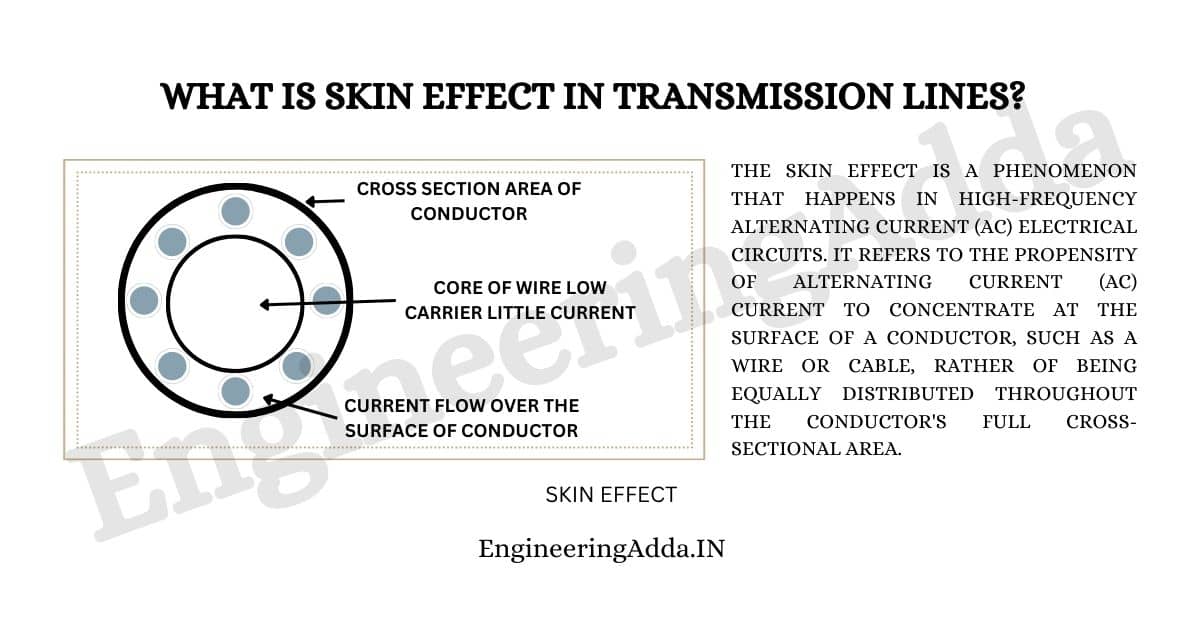

The skin effect is a phenomenon that happens in high-frequency alternating current (AC) electrical circuits. It refers to the propensity of alternating current (AC) current to concentrate at the surface of a conductor, such as a wire or cable, rather of being equally distributed throughout the conductor’s full cross-sectional area.

In other words, as the frequency of the alternating current signal rises, the current flow tends to be stronger towards the conductor’s outer edges or surface, while the core carries less current. This occurs because the fluctuating magnetic field created by the AC current causes “eddy currents” within the conductor at higher frequencies. These eddy currents, which are more concentrated towards the surface, counterbalance the main current flow.

The skin effect can cause greater resistance in a conductor by reducing the effective cross-sectional area through which current flows. This can result in increased power losses and conductor heating, which can be problematic in high-frequency applications or high-power transmission lines.

In materials with higher electrical resistivity and at higher frequencies, the skin effect is more evident. Conductors can be built with bigger diameters or composed of materials with lower resistance to reduce the influence of skin effects. Furthermore, utilizing multi-stranded conductors can assist distribute current more uniformly across the cross-sectional area, decreasing the detrimental consequences of the skin effect.

The Depth at Which Copper’s Skin Effect Occurs in Electrical Engineering

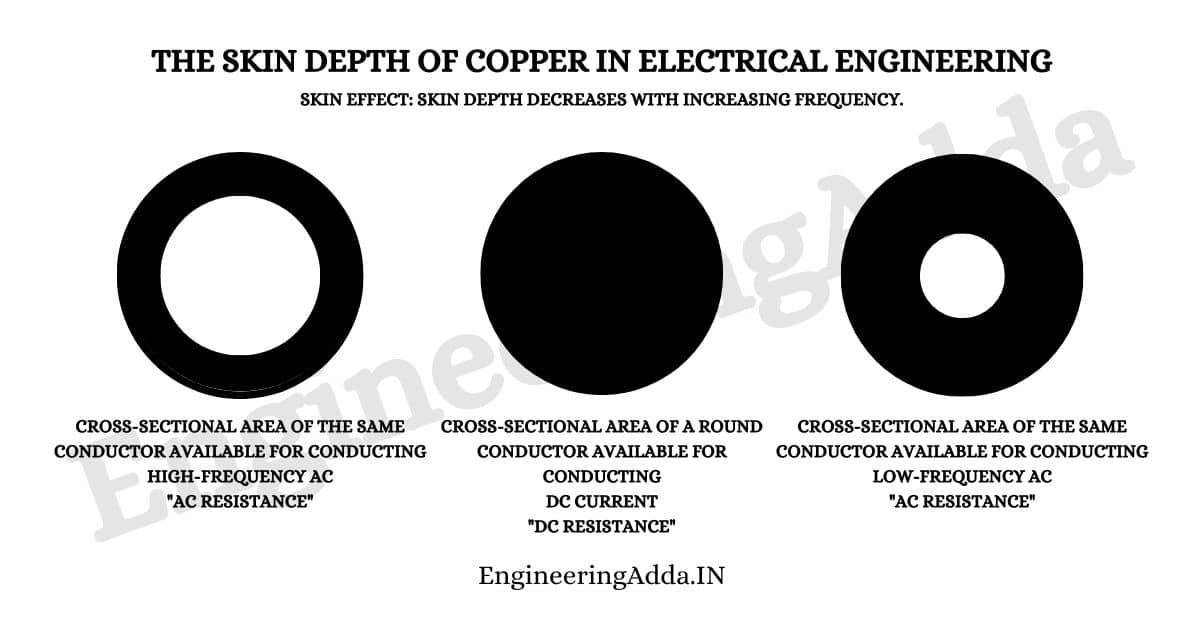

As we talked about earlier, the skin effect happens when AC electricity doesn’t really like to go through the middle of a solid wire. Instead, it mostly stays near the surface.

This means that the inside part of the wire doesn’t get used as much for carrying the wiggly electron flow in AC. Because of this, the wire’s resistance to AC electricity goes up more than it would for regular, steady DC electricity.

The resistance of a conductor when all its available cross-sectional area is utilized is referred to as “DC resistance.” In contrast, the term “AC resistance” signifies a higher value due to the influence of the skin effect.

When dealing with high frequencies, the AC current demonstrates a tendency to evade the majority of the conductor’s cross-sectional area. In terms of carrying current, the wire could be likened to being hollow. This means that much of the space inside the conductor remains unused by the AC current, leading to an increase in resistance.

This phenomenon can be likened to a busy road where cars prefer to stay on the edges rather than using the whole road. To cope with this behavior, engineers often employ strategies like using special wire designs or materials to encourage more uniform current distribution, thereby countering the effects of the skin effect and allowing efficient transmission of AC electricity.

Why Skin Effect Occurs In Power System

The skin effect occurs because of how alternating current (AC) interacts with the wire it’s flowing through. When AC electricity moves through a wire, it creates a sort of changing magnetic field around the wire. This magnetic field, in turn, creates small circular currents, often called eddy currents, within the wire itself.

These eddy currents act like little roadblocks to the main AC current. They oppose the main current’s flow, kind of like trying to swim against a strong current. In response to these eddy currents, the AC current adjusts its path. It chooses to flow more on the surface of the wire, where there’s less interference from these opposing eddy currents.

Think of it like a group of people trying to walk through a crowd. If there are lots of small obstacles in the middle of the crowd, they might decide to stick to the sides of the path to avoid the obstacles and move more easily.

As a result of this adjustment, the AC current concentrates more on the outer part of the wire, leaving the core with less current flow. This is why we call it the “skin” effect – the AC current likes to stay on the “skin” or surface of the wire.

As the AC frequency increases (meaning the current wiggles back and forth faster), the effect becomes even stronger. More of the current avoids the center of the wire and prefers to stay on the surface. This can be a bit like cars on a road staying close to the edges to avoid traffic in the middle.

In the end, the skin effect makes the wire’s core less effective at carrying AC current, leading to some inefficiencies and extra heat generation. Engineers use different techniques to manage this effect, ensuring that wires can efficiently handle high-frequency AC currents without losing too much energy or overheating.

Factors Affecting Skin Effect

Frequency of the AC Current: The skin effect becomes more pronounced as the frequency of the alternating current increases. Higher frequencies result in stronger magnetic fields around the conductor, leading to more significant eddy currents and pushing the AC current further towards the surface.

Conductor Material: The electrical properties of the conductor material play a role. Materials with higher electrical resistivity tend to experience a more pronounced skin effect. This is why some materials are chosen over others for applications involving high-frequency AC currents.

Conductor Size: The physical dimensions of the conductor matter. Thicker conductors have a reduced skin effect because the current has more space to spread out. However, for very high frequencies, even thicker conductors might not completely eliminate the effect.

Shape and Surface Area: The shape of the conductor also influences the skin effect. Hollow conductors or flat ribbon-shaped conductors experience less skin effect compared to round solid conductors. This is because the geometry affects how the eddy currents circulate within the conductor.

Permeability of Surroundings: The presence of magnetic materials or other conductors near the primary conductor can impact the skin effect. Magnetic materials can intensify the magnetic fields, affecting the distribution of eddy currents and the concentration of AC current on the surface.

Insulation and Coatings: The type of insulation or coating on the conductor can influence the skin effect. Some insulating materials can change the way eddy currents circulate, altering the distribution of AC current within the conductor.

Temperature: The skin effect’s impact can be affected by temperature changes. Higher temperatures can increase the electrical resistivity of the conductor material, potentially exacerbating the skin effect.

Effect on Electrical Conductors

The skin effect increases the effective resistance of a conductor, which in turn leads to higher impedance and power losses. These losses manifest as heat, potentially causing efficiency issues in high-power applications. Additionally, the behavior of the skin effect changes with frequency, with higher frequencies experiencing more pronounced effects.

Application in Power Transmission

In power transmission, the skin effect poses challenges for maintaining efficiency over long distances. High-frequency currents, often used in power lines, experience more severe skin effects. This effect influences the choice of conductor materials, transmission line designs, and the overall performance of the power grid.

Challenges in High-Frequency Circuits

In circuits operating at high frequencies, the skin effect can lead to uneven current distribution and signal loss. Engineers must contend with these challenges in designing circuits for applications like radiofrequency communication and high-speed data transmission.

Mitigation Techniques

Engineers employ various strategies to mitigate the skin effect’s impact. Litz wire construction involves weaving multiple insulated wires together to increase the effective surface area of the conductor. Hollow conductors minimize the interior material where current concentration occurs. Frequency optimization can also be utilized to reduce skin effect-related losses.

Skin Effect on Different Materials

While conductors experience the skin effect prominently, insulators and magnetic materials are also affected to varying degrees. Understanding these differences is crucial when designing systems that involve different types of materials.

Industrial and Practical Implications

The skin effect’s consequences are far-reaching, affecting industries from power generation and distribution to telecommunications and electronics manufacturing. Engineers must consider these effects when designing systems to ensure optimal performance and efficiency.

Advancements in Material Science

Material science advancements have led to the development of new conductor materials with reduced skin effects. Nanotechnology-based solutions offer the potential to further minimize this phenomenon and enhance the efficiency of electrical systems.

Read 6th to 12th From Botorzo.co.in